Here is a manufacturing process issue that turned out provide an interesting insight into how hot, liquid solder can react if it gets out of control.

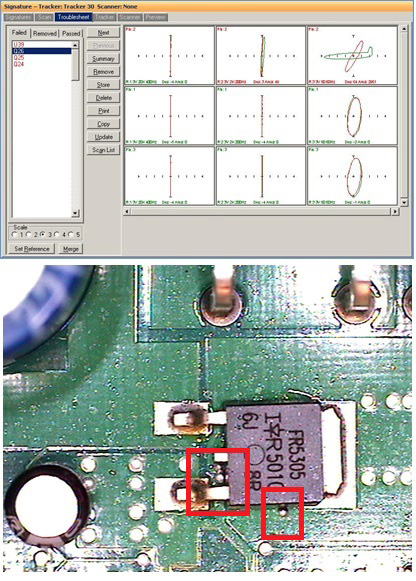

Initial testing with analog signature analysis shows a resistive difference on only one pin of a transistor (top image; top row of signatures, far right signature; green is good, red is bad). The change was fairly minor showing a lowering of resistance indicated by the signature’s change of angle. In a manufacturing environment, resistive changes like these usually turn out to be solder related, i.e. solder bridges. However, on closer inspection of the transistor, little balls of solder were discovered embedded around the pins of the device (bottom image).

Top image shows analog signatures of fault; the bottom image shows solder balls lodged around the transistor (red boxes).

From the best we could tell, ejected bits of molten solder fell on the PCB during reflow and rolled around lodging into cracks and crevices before cooling. Additional solder balls were discovered on the PCB but did not electrically affect the function. The problem detected and shown in the image above had the potential to cause serious damage if the PCB had made it to the power-on test stage further down the production line.